What Is A LED Chip? Understand Technology & Application

December 29, 2025

Read:192

Source: Ledestar

What Is A LED Chip? Understand Technology & Application

LED technology has revolutionized the lighting industry in recent decades, offering energy-efficient, long-lasting, and versatile lighting solutions. At the heart of all LED lighting is the LED chip, a tiny semiconductor component that emits light when electrically energized. Understanding LED chips, their sizes, optical and electrical parameters, and applications is essential for lighting engineers, manufacturers, and enthusiasts alike.

In this article, we will explore LED chips in detail, focusing on popular types like LED 2835, LED 3030, LED 3535, and LED 5050, their specifications, practical applications, and how to select the right LED chip for your lighting projects.

What Is an LED Chip?

An LED (Light Emitting Diode) chip is a semiconductor device that converts electrical energy directly into light through the process of electroluminescence. Unlike traditional incandescent or fluorescent lamps, LED chips produce light without heating a filament or using mercury vapor, making them more efficient, durable, and environmentally friendly.

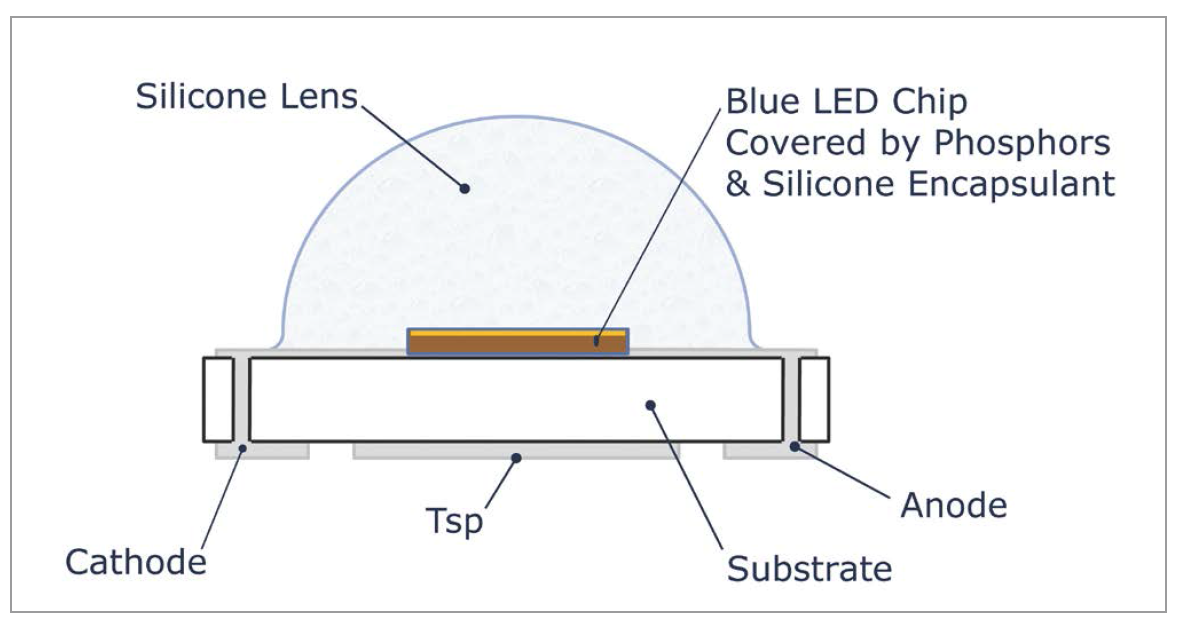

Structure of an LED Chip

A typical LED chip consists of:

Semiconductor substrate – usually made of materials like gallium nitride (GaN) or gallium arsenide (GaAs), forming the foundation for the chip.

P-N junction – the core layer where electroluminescence occurs. Electrons and holes recombine here to emit photons.

Electrodes – anode and cathode contacts that allow electrical current to flow through the chip.

Encapsulation layer – often a transparent epoxy or silicone layer to protect the chip and enhance light extraction.

Phosphor coating (for white LEDs) – converts part of the light into the desired color temperature.

The efficiency and performance of an LED largely depend on the quality of these materials and the manufacturing process.

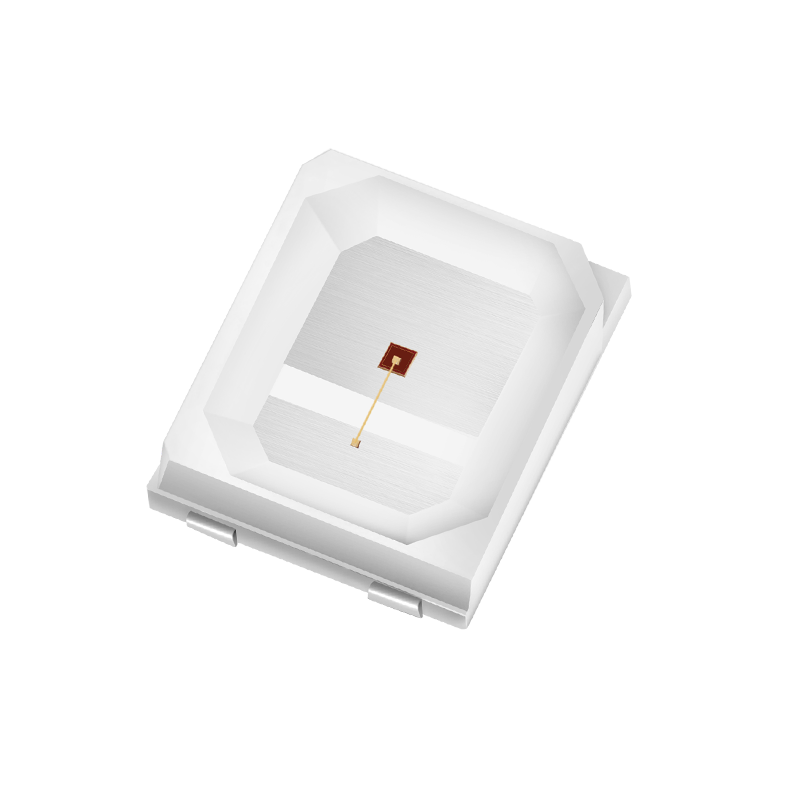

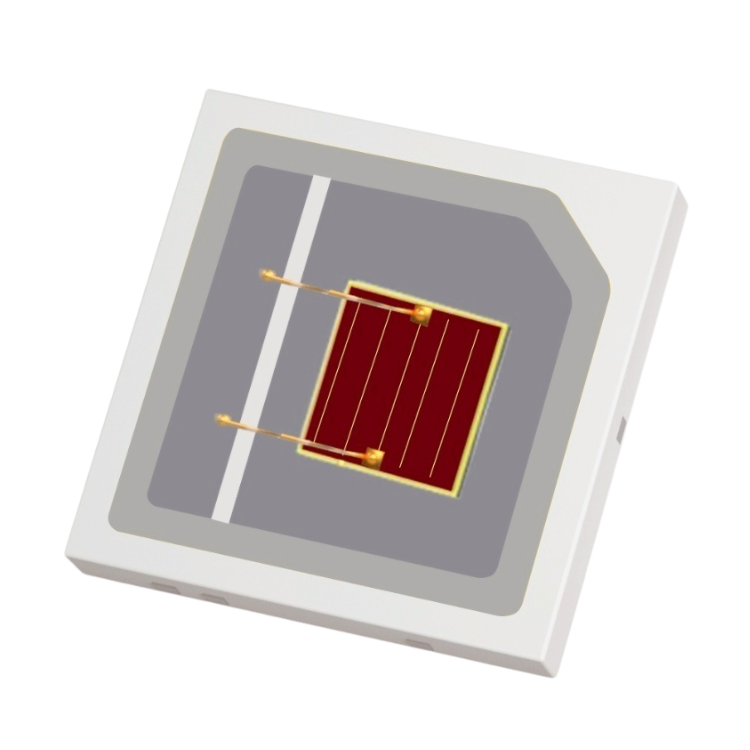

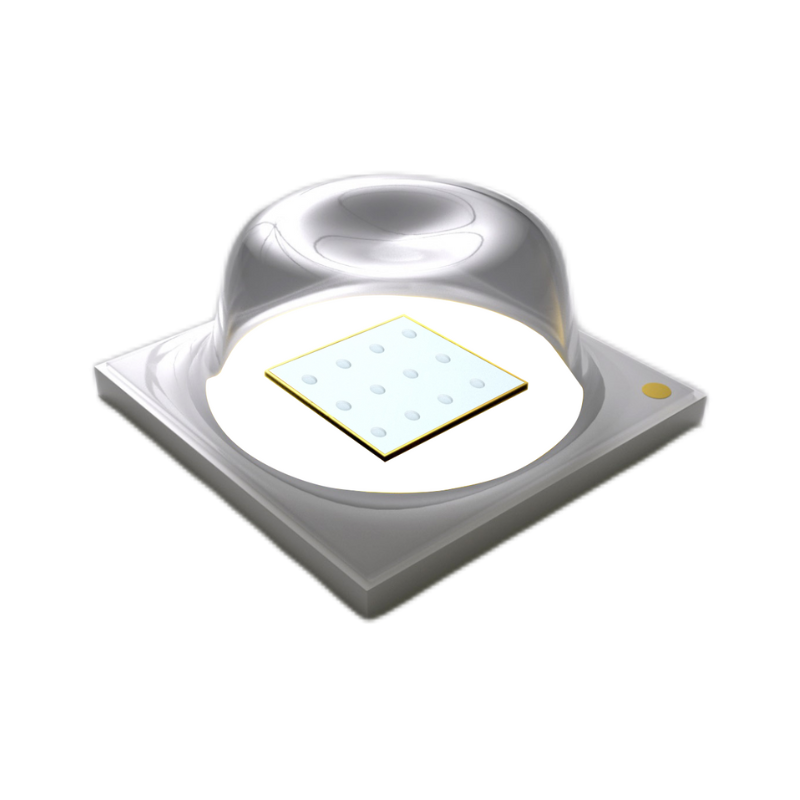

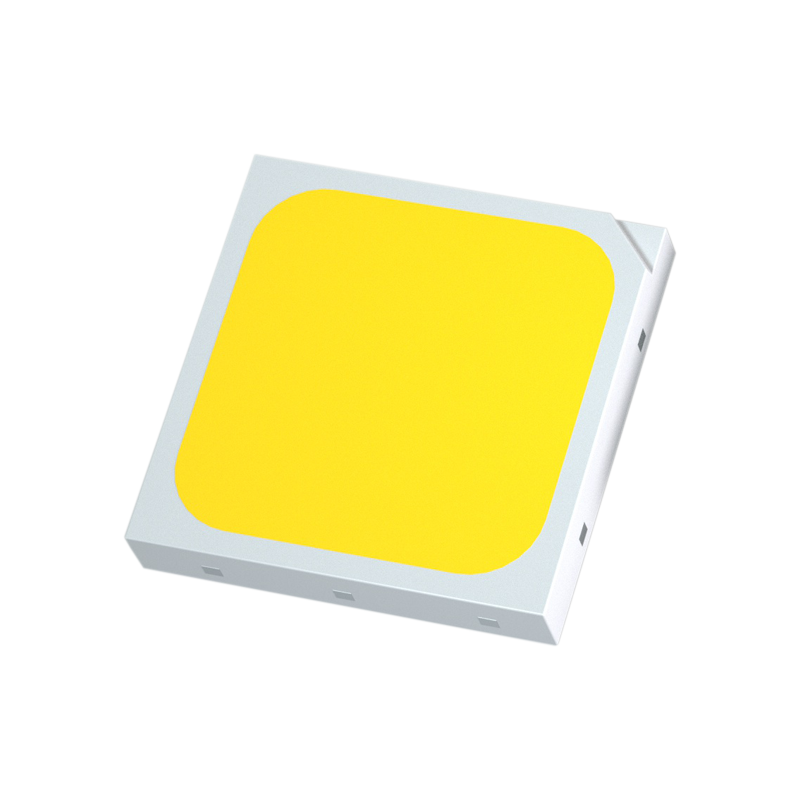

Common LED Chip Sizes: 2835, 3030, 3535, and 5050

LED chips come in various sizes and package types, influencing their brightness, heat dissipation, and application. Let’s examine the popular SMD (Surface-Mounted Device) LED chips:

| LED Chip | Dimensions (mm) | Typical Power (W) | Forward Voltage (V) | Available Colors | Typical Applications | |

|---|---|---|---|---|---|---|

| 2835 | 2.8 × 3.5 | 0.2–0.5 | 2.8–3.4 | LED strips, downlights, residential lighting | |

| 3030 | 3.0 × 3.0 | 0.2–1.5 | 2.8–3.6 | Panel lights, ceiling lights, street lights, horticulture lighting | |

| 3535 | 3.5 × 3.5 | 0.5–3 | 2.8–3.6 | High-brightness lighting, outdoor lighting, horticulture panels | |

| 5050 | 5.0 × 5.0 | 1–5 | 2.8–3.6 | LED strips, RGB decorative lighting, stage lights, outdoor displays |

Electrical and Optical Parameters

When evaluating LED chips, several key parameters determine performance and suitability for specific applications:

1. Forward Voltage (Vf)

The voltage drop across the LED chip when conducting. Lower forward voltage reduces power consumption, while higher voltage may indicate high-power chips.

2. Luminous Flux (lm)

The total amount of visible light emitted. High luminous flux is desirable for general illumination, whereas lower flux may suffice for accent lighting.

3. Luminous Efficacy (lm/W)

Efficiency measure: how much light output per unit of electrical power consumed. Higher efficacy reduces energy costs and heat generation.

4. Color Temperature (CCT)

Measured in Kelvins (K), CCT defines the color of white light. Typical ranges:

Warm White: 2700–3500 K

Neutral White: 4000–4500 K

Cool White: 5000–6500 K

5. Color Rendering Index (CRI or Ra)

A measure of how accurately colors appear under the light. High CRI (80–90+) is essential for retail, art, or indoor lighting.

6. Thermal Resistance (Rth)

LEDs generate heat; thermal resistance indicates how effectively heat is conducted away. Lower Rth ensures longer lifetime and consistent performance.

Applications of LED Chips

LED chips are versatile and widely adopted across various industries. Understanding the suitable application of each size and type is crucial for maximizing performance.

1. General Lighting

LED 2835 & 3030 are popular for residential, office, and commercial lighting.

Applications include bulbs, ceiling lights, panel lights, and downlights.

Emphasis on high efficiency, uniform light distribution, and long lifetime.

2. Outdoor and Street Lighting

LED 3535 & 5050 are widely used for street lamps, tunnel lighting, and landscape lighting.

High luminous flux and robust thermal performance are critical in these applications.

Long-term reliability ensures safety and energy savings.

3. Decorative and Entertainment Lighting

LED 5050 with RGB or multi-color capabilities is ideal for LED strips, architectural lighting, and stage effects.

Ability to integrate multiple colors in a single chip reduces complexity in design and wiring.

4. Horticulture Lighting

LEDs are transforming agriculture with controlled spectrum solutions.

LED 3030 & 3535 chips with red (660 nm), blue (450 nm), and far-red (730 nm) wavelengths improve plant growth and flowering.

Tailored optical parameters such as PPFD (Photosynthetic Photon Flux Density) enhance cultivation efficiency.

5. Specialty Applications

UV LEDs for sterilization and curing applications.

Infrared LEDs for security, sensing, and therapy devices.

Small form-factor LED chips provide flexibility in compact devices.

Selecting the Right LED Chip

When choosing an LED chip, consider these factors:

Power and Brightness Requirements: Higher power chips like 3535 and 5050 are suitable for high-intensity lighting.

Thermal Management: Ensure the heat dissipation design matches chip thermal resistance.

Color Needs: Select CCT and CRI according to application; warm white for residential, neutral/cool white for offices.

Size Constraints: SMD size determines how many chips fit on a PCB or light fixture.

Cost vs. Efficiency: Balance budget constraints with luminous efficacy and lifetime.

Advances in LED Chip Technology

Modern LED chips are evolving in multiple ways:

Higher Luminous Efficacy: New materials and packaging reduce energy consumption.

Improved Thermal Design: Ceramic substrates and advanced heat sinks prolong lifespan.

Custom Spectrums: Tailored phosphors and multi-die chips for horticulture, medical, and therapy lighting.

Miniaturization: Smaller chips for compact applications without compromising light output.

These advancements make LED chips not only energy-efficient but also highly versatile across industries.

Conclusion

An LED chip is the core of modern lighting technology, offering efficient, durable, and versatile light sources. Understanding chip sizes like LED 2835, 3030, 3535, and 5050, their electrical and optical parameters, and suitable applications is critical for engineers, manufacturers, and designers. From general illumination to horticulture, street lighting, and decorative projects, choosing the right LED chip ensures optimal performance, energy efficiency, and long-term reliability.

Whether you are designing a small residential LED fixture or a large-scale horticulture lighting system, mastering LED chip technology allows you to leverage the full potential of this transformative lighting solution.

Table of Contents