What is SMD and COB LED?

January 10, 2026

Read:253

Source: Ledestar

What Is an SMD LED and a COB LED?

A Technical and Application-Oriented Comparison

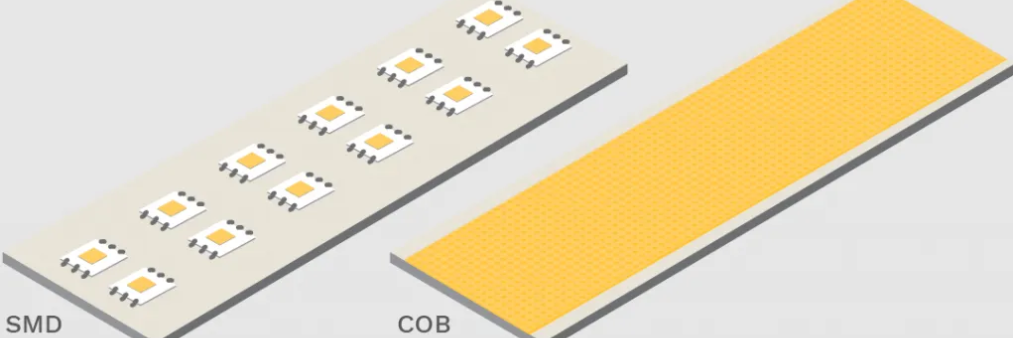

As LED technology continues to mature, packaging has become one of the most decisive factors affecting LED performance, reliability, and application suitability. Among the many packaging solutions developed for solid-state lighting, SMD LED (Surface-Mounted Device) and COB LED (Chip on Board) stand out as the two most widely adopted and technically mature technologies.

Although both SMD and COB LEDs are based on the same semiconductor light-emission principles, their packaging structure, physical scale, optical behavior, and application orientation differ significantly. These differences explain why SMD LEDs are primarily associated with high luminous efficacy and system flexibility, while COB LEDs—especially in power classes above 50W—are favored for high-power, high-intensity lighting applications.

This article analyzes SMD and COB LEDs from three closely related perspectives: packaging method, size and structural characteristics, and application direction, with a focus on practical engineering considerations rather than isolated parameters.

1. Packaging Method: Structural Design and Engineering Logic

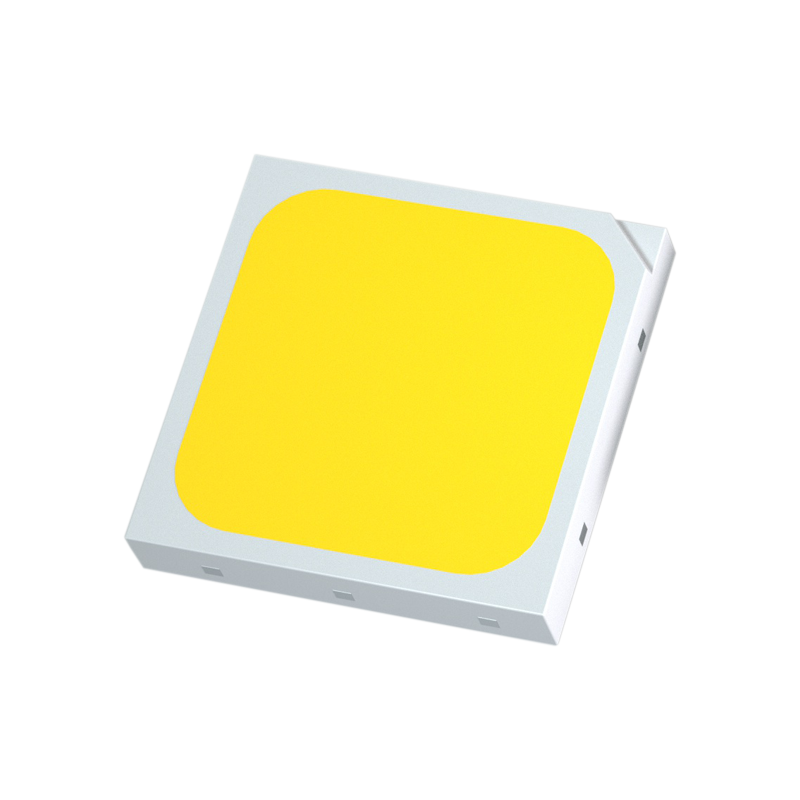

SMD LED Packaging: Discrete Structure Optimized for Efficiency

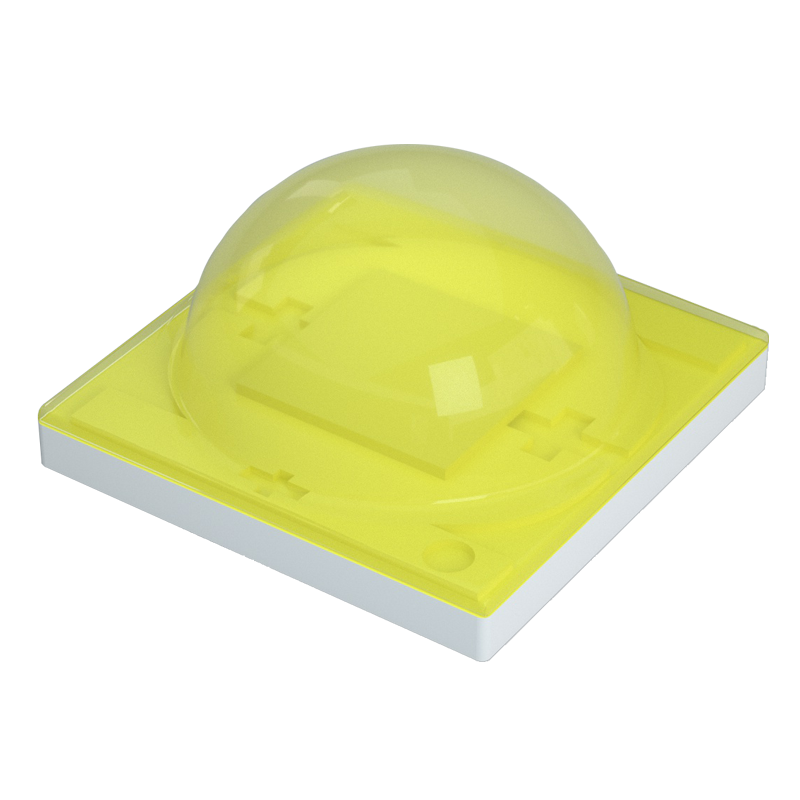

SMD LEDs adopt a discrete packaging structure, in which one or several LED chips are mounted onto a lead frame or ceramic substrate. Electrical connections are achieved through wire bonding or flip-chip bonding, and the entire assembly is encapsulated with optical-grade silicone or epoxy resin.

From an engineering perspective, this packaging method offers several core advantages:

Independent optical control for each LED package

Stable electrical characteristics with high production consistency

Excellent compatibility with automated SMT assembly

Because each SMD LED functions as an individual light source, thermal energy is dissipated through the package into the PCB and then into the system-level heat management structure. This makes SMD LEDs particularly suitable for low to medium power operation, where thermal equilibrium and luminous efficacy can be optimized simultaneously.

Over years of development, SMD LED packaging has been refined to maximize light extraction efficiency, which is why SMD LEDs are widely recognized for their high lm/W performance, especially in outdoorl and commercial lighting applications.

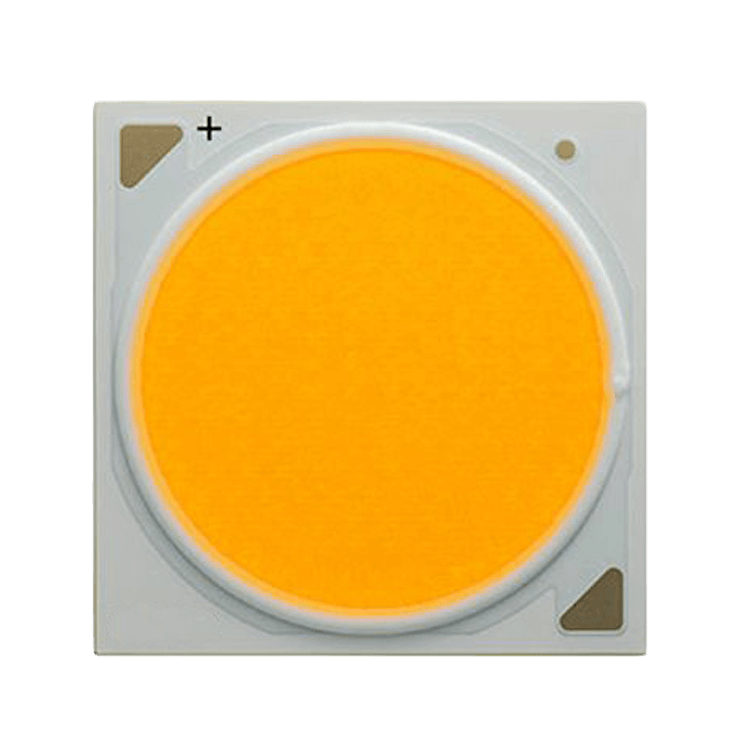

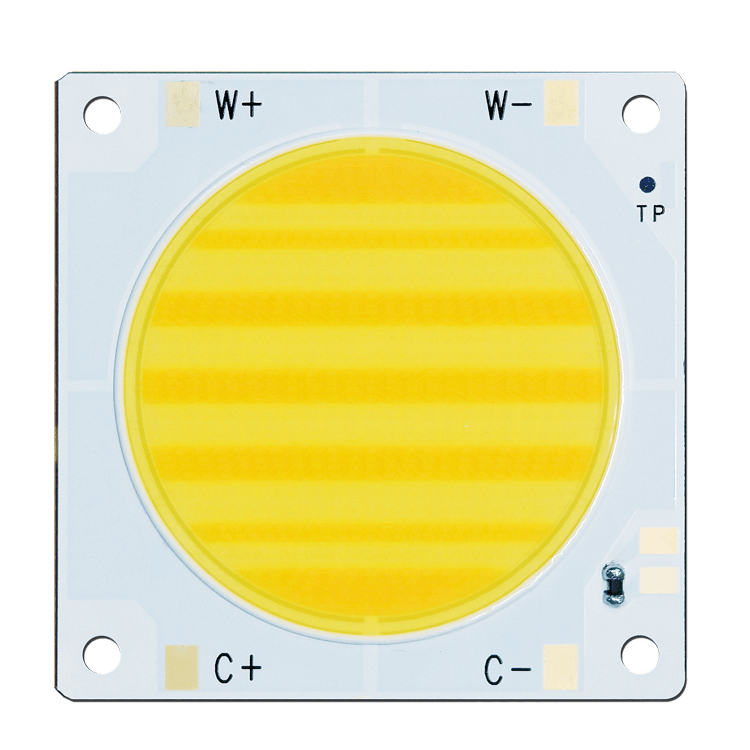

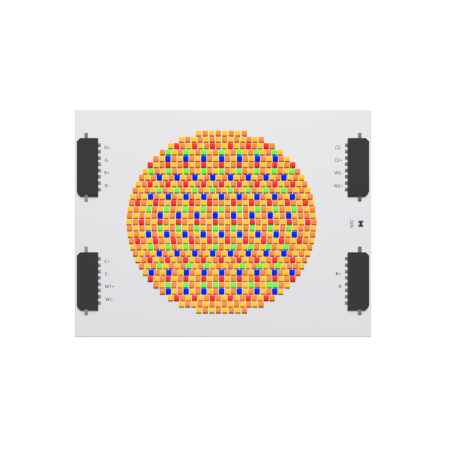

COB LED Packaging: High Integration for High Power Density

COB LED packaging follows a fundamentally different concept. Instead of packaging LED chips individually, multiple bare LED dies are directly mounted onto a single substrate, typically aluminum or ceramic. These chips are electrically interconnected to form a unified light source, and a continuous phosphor layer is applied over the entire chip array.

This integrated structure leads to several defining characteristics:

A single, uniform light-emitting surface (LES)

Very high chip density, enabling high power operation

Reduced optical losses between individual chips

COB packaging is especially advantageous in 50W, 100W, and higher power ranges, where using large numbers of discrete SMD LEDs would increase system complexity. However, the high integration level also means that COB LEDs rely heavily on efficient thermal conduction from the substrate directly to the heat sink. As a result, thermal design is a critical success factor in high-power COB lighting systems.

Ledestar SMD & COB Prodcuts

SMD

| Prodcut | LED | Power | Lumen Efficiency |

| 2835-282K | 0.2W | 260lm/W |

| 3030-304K | 1W | 235lm/W |

| 3535-351V | 1W | 210lm/W |

| 5050-510T | 1W | 250lm/W |

COB

| White COB | Bi-Color COB | RGBW COB |

|  |  |

2. Size and Structural Characteristics

Standardized SMD LED Sizes and Their Practical Meaning

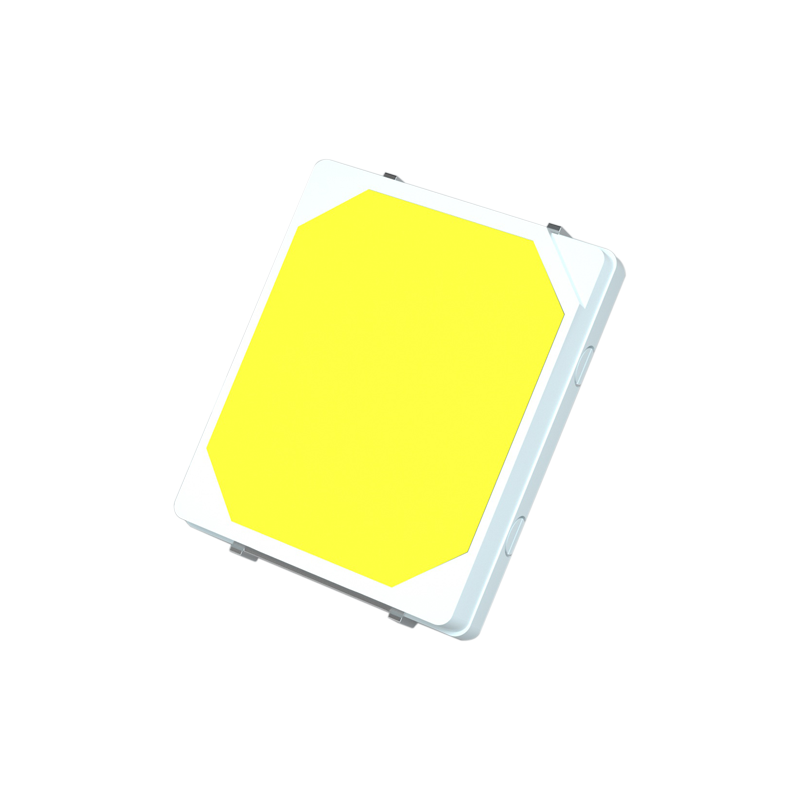

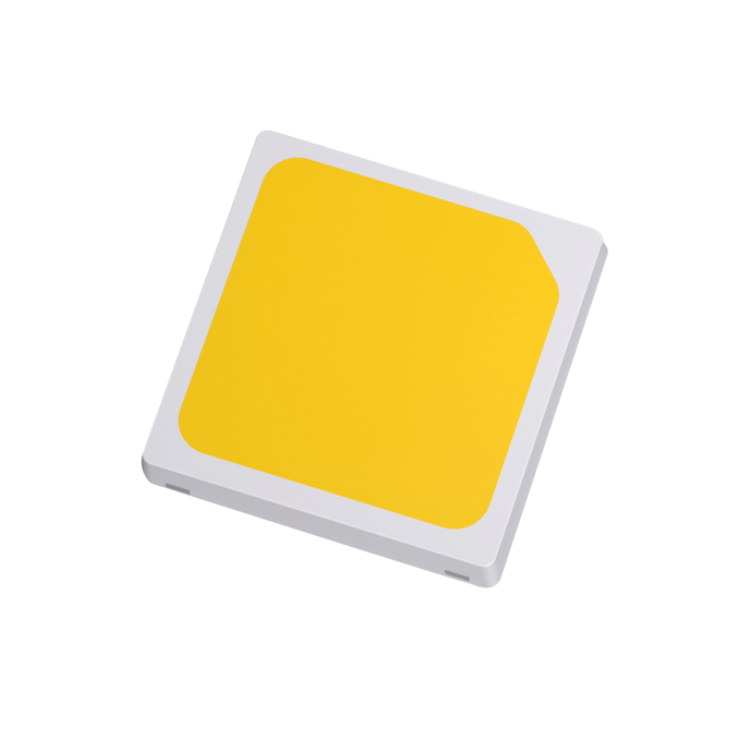

One of the strengths of SMD LEDs lies in their standardized size formats, commonly identified by numerical designations such as 2835, 3030, 3535, and 5050. While these numbers simply describe physical dimensions, each size category reflects a specific balance between power handling capability and thermal performance.

2835 (2.8 × 3.5 mm)

3030 (3.0 × 3.0 mm)

3535 (3.5 × 3.5 mm)

5050 (5.0 × 5.0 mm)

In practical lighting design, these standardized packages allow engineers to:

Adjust LED quantity to control total luminous flux

Optimize layout for uniform light distribution

Balance efficiency, cost, and thermal reliability

Because SMD LEDs are discrete components, they can be arranged in linear arrays, matrices, or customized PCB layouts. This structural flexibility is one of the key reasons SMD LEDs dominate efficiency-driven lighting systems, where uniformity and system efficacy are critical.

COB LED Size Characteristics in High-Power Designs

COB LEDs are not classified by standardized package dimensions. Instead, they are defined by parameters such as:

Light Emitting Surface (LES) diameter

Total power rating (commonly ≥50W)

Luminous flux and thermal interface size

In high-power COB LEDs, the emitting surface is intentionally enlarged to distribute current density and reduce localized thermal stress. This structural design enables stable operation under high drive currents while maintaining optical uniformity.

From an optical standpoint, the single LES allows efficient coupling with reflectors and lenses, making COB LEDs highly suitable for directional and focused lighting applications.

3. Optical Performance and Luminous Efficacy

SMD LEDs are primarily engineered to achieve maximum luminous efficacy. Their discrete packaging, optimized chip structures, and refined phosphor systems allow efficient light extraction and low optical loss. As a result, SMD LEDs often outperform other packaging types in terms of lm/W, especially at typical operating currents.

COB LEDs, while still efficient, are optimized for luminous flux density rather than peak efficacy. In high-power lighting systems, overall performance depends more on thermal stability, optical utilization, and beam control than on chip-level efficiency alone. This difference in optimization goals explains the distinct application positioning of the two technologies.

4. Application Direction

SMD LEDs: Efficiency-Oriented and Flexible Lighting Systems

SMD LEDs are widely used in applications where energy efficiency, scalability, and layout flexibility are key priorities. Typical application areas include:

Commercial and residential general lighting

Panel lights and linear luminaires

Industrial lighting systems

Horticulture and specialty lighting requiring spectral customization

In these scenarios, SMD LEDs enable designers to build modular, high-efficiency lighting systems with excellent uniformity and long-term reliability.

COB LEDs: High-Power and High-Intensity Lighting Applications

COB LEDs dominate applications that require high luminous flux from a compact source, particularly above 50W. Common use cases include:

High-bay and industrial luminaires

Floodlights and stadium lighting

Architectural spotlights and downlights

The integrated structure of COB LEDs simplifies optical design and reduces component count, making them ideal for professional lighting systems operating under demanding conditions.

Conclusion

SMD and COB LEDs represent two complementary LED packaging technologies rather than competing solutions. SMD LEDs excel in high luminous efficacy and flexible system design, while COB LEDs—especially in power ranges above 50W—are optimized for high-power, high-intensity lighting. A clear understanding of their structural and performance differences allows lighting professionals to select the most appropriate technology for each application.

Table of Contents