Manufacturing Capacity

Ledestar operates with a robust production infrastructure designed to meet the high demands of global lighting markets.

Our manufacturing ecosystem integrates technical expertise, advanced automation, and rigorous quality control.

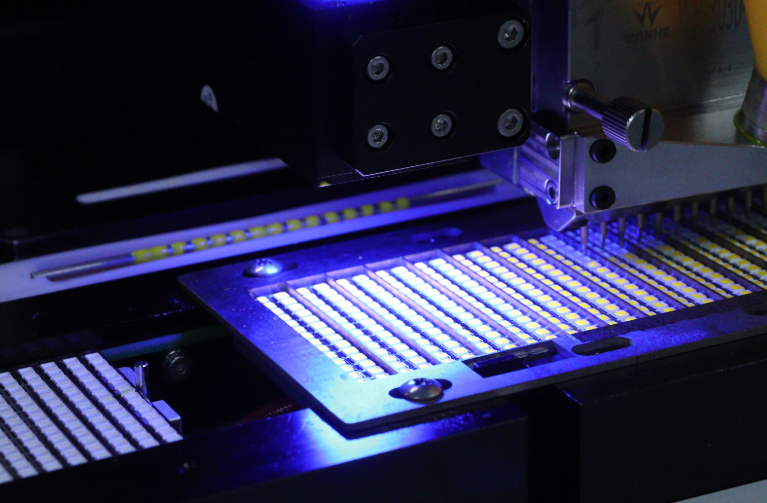

Quality Control

Advanced automated testing systems ensure each product meets rigorous standards for reliability, consistency, and performance

Solutions Showcase

Full Spectrum LED

Our full-spectrum LEDs simulate natural sunlight by covering UV, blue, green, red, and far-red wavelengths. Ideal for human-centric lighting, plant growth, and visual applications requiring precise spectral control.

Microalgae Led Solution

We offer tailored solutions for modules, LED quantity, spectrum, and color temperature. Every design adapts to your specific application needs.

LM-80 Test Report

All of our high-power LEDs are backed by LM-80 test reports from authorized third-party labs, ensuring proven long-term lumen maintenance and thermal reliability for demanding applications.

Horticulture LED Solution

Tailored horticultural lighting solutions with adjustable spectra for different crop stages—germination, vegetative, and flowering. Optimized for vertical farms, greenhouses, and indoor agriculture.

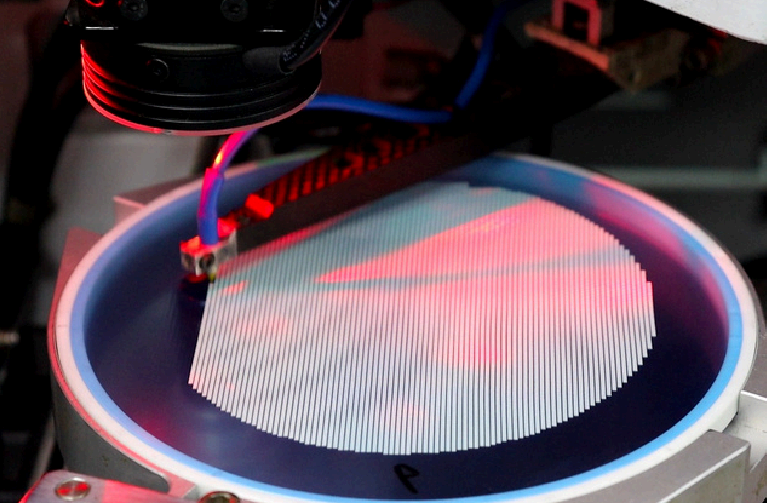

Horticulture LED Lab

Ledestar has been specializing in horticulture LED manufacturing for over a decade. We not only provide the production and sales of LED chips but also have established a horticulture lighting research laboratory within our factory. In this lab, we focus on studying various spectral solutions and conduct experiments using our LED chips. Our goal is to simulate real-world growing conditions, offering lighting companies optimized solutions for their products.